|  |  |

|---|---|---|

|  |  |

|  |  |

|

♦ Bore Water / Groundwater / Seawater / Ballast Water / Surface Water / Industrial Water Filtration

♦ Cooling Circulating Water

♦ Heat Exchanger Protection

♦ Machining Coolant Treatment

♦ Biomass power station

♦ Coal power station

♦ Gas power station

♦ Nuclear Power station

♦ Marine

♦ Offshore

♦ FSRU

♦ REGAS

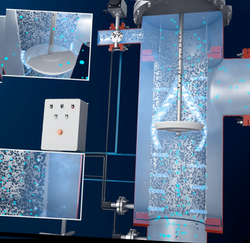

AF Bernoulli Back-Flushing Filter

AF Bernoulli back-flushing self-cleaning filter is designed for automatic continuous coarse filtration ranging from 200μm to 2000μm in the pressurized systems. AF filter works in Bernoulli Effect Principle, which leads to the simple and reliable filtering operation. AF filter can remove debris and particles in the natural water sources such as sea water or river water. Cleaning the filter screen with surface cross flow and back-flushing flow produces higher particle removal efficiency than the conventional brush filter. Particles which are larger than the screen aperture will be extruded through the screen when a brush disc is brushing and cleaning.

WORKING PRINCIPLE

The flushing sequence is initiated by a timer setting or triggered by a differential pressure sensor before any blockage of the filter screen causing flow reduction.

In the pre-flushing stage, the flushing valve opens and larger particles are flushed out.

During the flushing sequence, a special shaped flushing disc mounted on a piston shaft is driven by a pneumatic cylinder moves up and down in the filter basket.

Because of the gap between the disc and the inner surface of the filter screen, the flow velocity increases locally around the disc, the static pressure is reduced in accordance with the Bernoulli Principle. The direction of the flow is reversed and the vacuum effect of lower static pressure back-flushes the filter screen inside surface with the filtered water. Thus it releases particles which are stuck to the surface of the filter basket.

The released particles are led out from the filter through the flushing outlet.

DESIGN SPECIFICATIONS

Standard Design Pressure: 0.6 / 1.0 / 1.6 / 2.5 Mpa

Design Temperature: 80°C

Flow Rate: 30-6500 m³/h

Filtration Rating: 200-2000µm

Largest Removable Particle: 6mm

Housing Wet Part Material: SS304 / SS316L / Duplex 2205 / CS (Rubber Lining) / GRP

Filter Element: 304 / 316L / Duplex2205 Wedgewire slotted metal filter screen / POR series laser-cutting pore screen

Inlet and Outlet Standard Flange: DN65 - DN800 HG20592-2009 (DIN compatible), HG20615-2009 (ANSI B16.5 Compatible), AS2129 Table Flange, BSP/NPT screwed connection

Piston Rod Material: 316L

Piston Rod Seal: PU

Housing Seal Material: NBR/EPDM/VITON/Silastic/FEP encapsulated Silastic

Element Seal Material: NBR/EPDM/VITON/Silastic/FEP encapsulated Silastic

Piston Rod Seal Material: NBR/PU/VITON

Cleaning Pressure Drop: 11Kpa

Differential Pressure Instrument: Differential pressure transmitter (DPT) / Differential pressure switch (DPS)

Flushing Valve: Pneumatic butterfly valve

Supply Facility Requirement: 220V / 240V / 380V AC, 0.4 - 0.6 Mpa clean and dry compressed air

APPLICATIONS

Applicable System: water treatment pre-filtration, circulating cooling system, heat exchanger protection, spraying nozzle protection, ballast water treatment system, ultra-filtration membrane protection

Applicable Fluids: underground water, sea water, lake water, river water, circulating cooling water, sewage water, process water, cleaning water, etc.

TECHNICAL FEATURES AND ADVANTAGES

Two moving parts: cleaning disc and flushing valve)

Simple and reliable design.

Easy to maintain

Non-contact back-flushing cleaning, no particle larger than the screen aperture extruded through the filter screen

Short, adjustable flushing time and minimum pressure drop in the system during flushing

Small variable flush rates

Excellent corrosion resistance

Working pressure is ranging from 0.3 bar to 25 bar

Consistent low pressure drop (<11 Kpa)

Wide flowrate ranging from 30 to 6500 m³/h with one single filter housing

Filtration rating ranging from 200μm to 2000μm

Flexible installation in the horizontal or vertical position